Ο τροχός ταξινόμησης στον μύλο ταξινομητή αέρα (ACM) παίζει κρίσιμο ρόλο στη διαδικασία λείανσης. Η κύρια λειτουργία της ταξινόμησης τροχού στον μύλο ταξινομητή αέρα είναι η ταξινόμηση των σωματιδίων σκόνης κατά λεπτότητα.

Συγκεκριμένα, οι ρόλοι του τροχού ταξινόμησης στο μύλο ταξινομητή αέρα περιλαμβάνουν κυρίως τις ακόλουθες πτυχές:

1. Προκαταρκτική λείανση υλικού

Όταν το υλικό εισέλθει στον θάλαμο λείανσης, ο τροχός ταξινόμησης αρχίζει να λειτουργεί. Μέσω της περιστροφής υψηλής ταχύτητας, ο τροχός ταξινόμησης μπορεί να δημιουργήσει ισχυρή φυγόκεντρη δύναμη, έτσι ώστε το υλικό να μπορεί να ταξινομήσει με φυγόκεντρη δύναμη. Προσαρμόζοντας την ταχύτητα του τροχού ταξινόμησης και το μέγεθος του ανοίγματος ταξινόμησης, το υλικό μπορεί να ταξινομηθεί σε διαφορετικές ποιότητες για να καλύψει διαφορετικές ανάγκες σε διαφορετικές εφαρμογές.

2. Επαγωγή ροής αέρα

Ο τροχός ταξινόμησης μπορεί να ρυθμίσει την ταχύτητα και την κατεύθυνση της ροής του αέρα. Με βάση τη δομή και την περιστροφή, ο τροχός ταξινόμησης μπορεί να προσαρμόσει την ταχύτητα και την κατεύθυνση της ροής αέρα. Όταν το υλικό διέρχεται από την πτερωτή του ταξινομητή, η περιστροφή υψηλής ταχύτητας του δίσκου τροχού θα διαχωρίσει τη σκόνη και θα άφηνε χονδροειδή σωματίδια στον δίσκο του τροχού για εκ νέου λείανση.

3. Επεξεργασία σωματιδίων

Καθώς τα σωματίδια ανεβαίνουν στον τροχό ταξινόμησης, αντιμετωπίζουν δύο αντίθετες δυνάμεις: τη φυγόκεντρη δύναμη από τον τροχό ταξινόμησης και την αντίσταση του αέρα από τη ροή αέρα. Τα λεπτότερα σωματίδια επηρεάζονται λιγότερο από τη φυγόκεντρη δύναμη και αφήνουν τον μύλο με ροή αέρα, ενώ τα πιο χονδροειδή σωματίδια ρίχνονται πίσω στον θάλαμο άλεσης για περαιτέρω λείανση.

4. Προσαρμογή παραμέτρων

Ρυθμίζοντας την ταχύτητα του τροχού ταξινόμησης κατά τη λειτουργία μπορεί να ελέγξει το μέγεθος των σωματιδίων. Η υψηλότερη ταχύτητα μπορεί να αυξηθεί φυγόκεντρη δύναμη και φιλτράρουν μεγαλύτερα σωματίδια πιο αποτελεσματικά, ενώ η χαμηλότερη ταχύτητα επιτρέπει τη διέλευση περισσότερων λεπτών σωματιδίων. Η δομή του τροχού, συμπεριλαμβανομένου του ύψους και του αριθμού της πτερωτής, μπορεί επίσης να επηρεάσει την ταχύτητα ροής αέρα και την απόδοση ταξινόμησης.

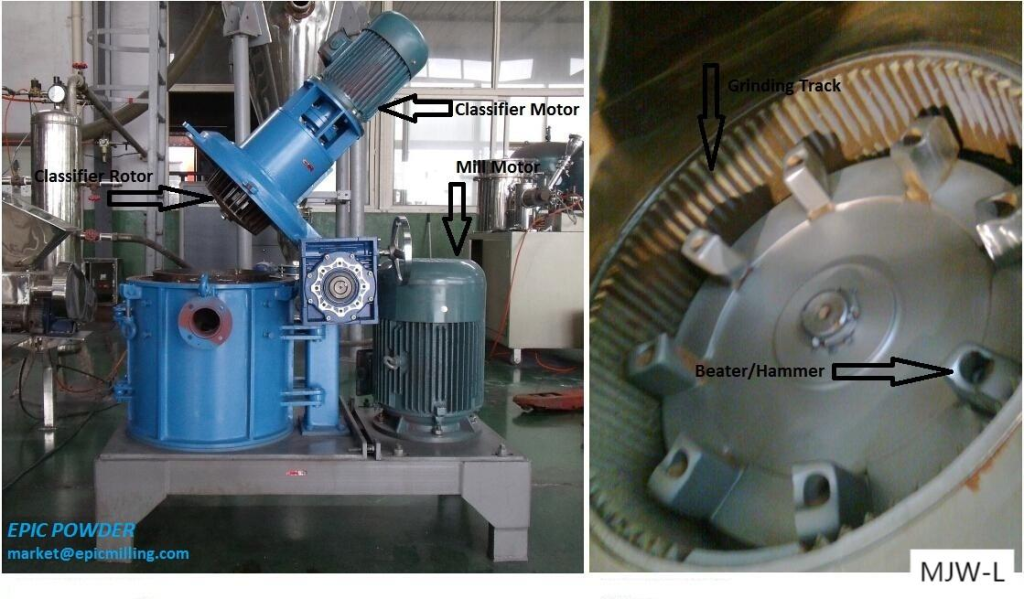

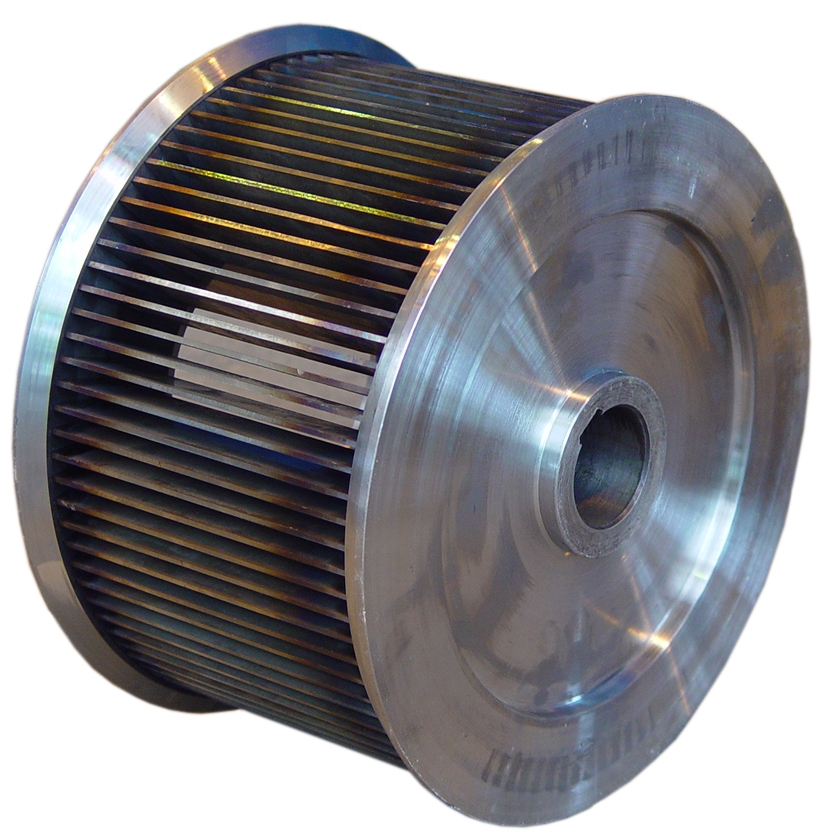

Ο τροχός ταξινόμησης από το Qingdao Epic παρακάτω

5. Συνεχής λειτουργία

Ολόκληρο το σύστημα λειτουργεί σε κατάσταση κλειστού βρόχου όπου τα χονδροειδή σωματίδια συνεχίζουν να ανακυκλώνονται μέχρι να φτάσουν την επιθυμητή λεπτότητα. Σε σύγκριση με το σύστημα που απαιτεί ξεχωριστό βήμα ταξινόμησης, η ενσωμάτωση της λείανσης και της ταξινόμησης σε μια ενιαία μονάδα μπορεί να βελτιώσει την απόδοση της εργασίας και να μειώσει το λειτουργικό κόστος.

Περίληψη

Ο τροχός ταξινόμησης στον μύλο ταξινομητή αέρα είναι ζωτικής σημασίας για την επίτευξη ακριβούς κατανομής μεγέθους σωματιδίων, επειδή μπορεί να εξισορροπήσει τη φυγόκεντρη δύναμη και την αντίσταση του αέρα μέσα στο δυναμικό περιβάλλον ροής αέρα. Αυτός ο σχεδιασμός έχει τα πλεονεκτήματα του ότι μπορεί να χειρίζεται τα υλικά αποτελεσματικά και να διατηρεί λειτουργική ευελιξία.

Qingdao Epic Powder Machinery Co., Ltd. είναι α κατασκευαστής που ειδικεύεται στην παραγωγή εξοπλισμού επεξεργασίας σκόνης.

Τα προϊόντα της περιλαμβάνουν:

– Μύλος: μύλος ταξινομητή αέρα, σφαιρόμυλος, κυλινδρόμυλος, μύλος εκτόξευσης, μύλος δόνησης και κρουστικός μύλος κ.λπ.

– Ο μύλος ταξινομητή αέρα περιλαμβάνει: MJW-W, MJW-A, MJW-L, MJL-W και Μύλος ταξινομητή αέρα εργαστηρίου.

– Classifier: τέσσερις σειρές ταξινομητών αέρα: HTS, ITC, MBS και CTC.

– Τροποποιητής: τροποποιητής μύλος καρφίτσας, τροποποιητής στροβιλομύλος και τροποποιητής τριών κυλίνδρων κ.λπ.

– Βοηθητικός εξοπλισμός: ντουλάπι ελέγχου, συλλέκτης σκόνης και ασανσέρ κουβά κ.λπ.

– Οι πελάτες μπορούν επίσης να προσαρμόσουν ανάλογα με τις ανάγκες τους, ένας πελάτης ένα σχέδιο.

Εάν έχετε σχετικές ανάγκες ή ερωτήσεις, παρακαλώ επικοινωνήστε με το προσωπικό από Έπος Qingdao απευθείας, είναι πάντα στη διάθεσή σας.

Παρακάτω είναι τέσσερις σειρές μύλων ταξινόμησης αέρα από την Qingdao Epic για μύλους ταξινομητή αέρα για την αναφορά σας.