En la industria farmacéutica, la calidad de los medicamentos está directamente relacionada con la vida y la salud, y los indicadores de la materia prima, como el tamaño de las partículas y la pureza, están estrechamente relacionados con la calidad de los medicamentos. Maquinaria de polvo épico de Qingdao Co., Ltd. es un fabricante Nos especializamos en la producción de equipos para el procesamiento de polvos. Nuestros productos incluyen: molino clasificador de aire, molino de rodillos, molino de bolas, molino de chorro, diversos clasificadores de aire, modificador de molino de pines, modificador de molino de tres rotores, etc.

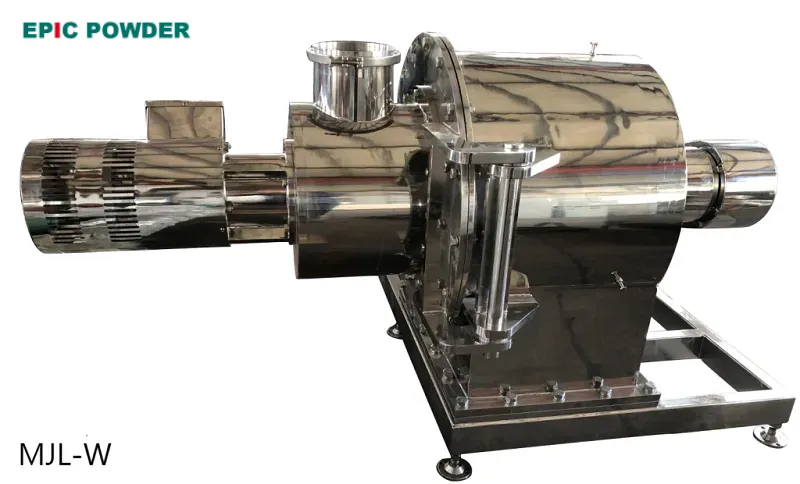

Gracias a nuestros años de experiencia y a la acumulación de conocimientos técnicos, comprendemos a la perfección el rendimiento y las características de los molinos clasificadores de aire. Nuestros molinos clasificadores de aire incluyen cuatro tipos: MJW-L, MJW-W, MJW-A, y MJL-WTienen una calidad estable, un rendimiento excelente y buenos comentarios de los clientes.

El molino clasificador de aire se usa ampliamente en muchas industrias, entre las cuales la industria farmacéutica es una industria de aplicación importante del molino clasificador de aire, porque es una herramienta importante para moler materias primas farmacéuticas.

Características del molino clasificador de aire adecuado para la molienda de materias primas farmacéuticas.

1. Molienda ultrafina, distribución uniforme del tamaño de partícula.

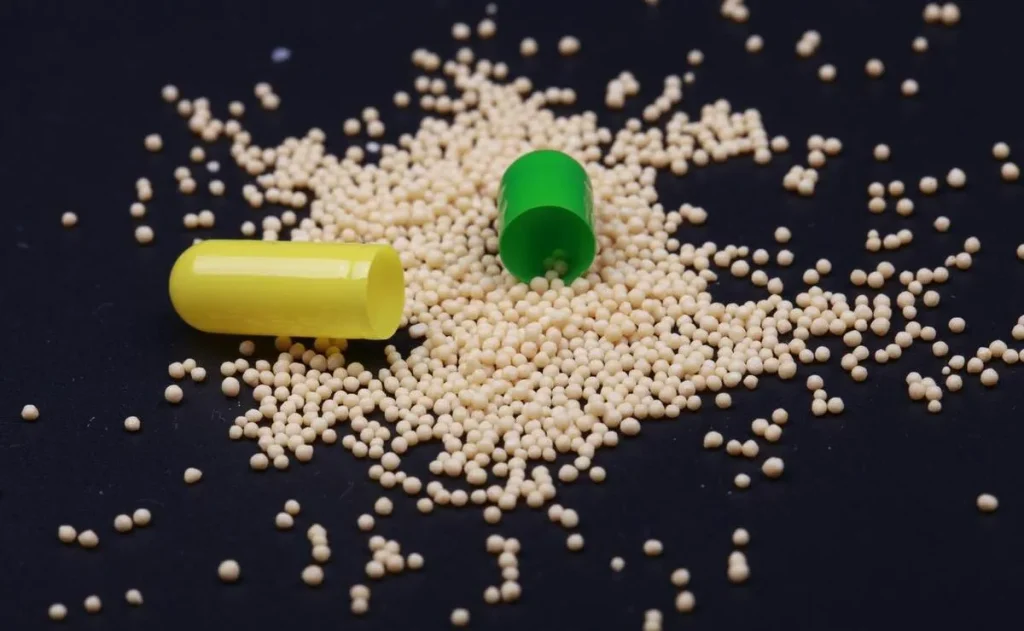

El molino clasificador de aire adopta principios aerodinámicos avanzados para moler la materia prima en micrones o incluso nanoescala Con una distribución granulométrica concentrada, esto puede mejorar eficazmente la disolución y la biodisponibilidad del fármaco.

2. Molienda a baja temperatura para proteger la actividad del fármaco.

Se generará menos calor durante el proceso de molienda. Esto evita eficazmente la inactivación de los ingredientes farmacológicos sensibles al calor y garantiza su eficacia.

3. Diseño completamente cerrado para evitar la contaminación.

El molino clasificador de aire adopta una estructura completamente cerrada para evitar la contaminación externa, cumplir con los requisitos de certificación GMP y garantizar un entorno de producción farmacéutica limpio y estéril.

4. Diseño modular, fácil operación y mantenimiento.

El molino clasificador de aire tiene una estructura compacta y diseño modularEsto permite que el desmontaje y el mantenimiento se realicen de forma sencilla, reduciendo así los costes operativos.

5. Control inteligente, preciso y eficiente.

Está equipado con un avanzado sistema de control PLC. Este sistema permite un funcionamiento automático que controla con precisión los parámetros de molienda, mejorando así la eficiencia de producción y la consistencia del producto.

Materias primas farmacéuticas aptas para molienda con molino clasificador de aire

● Antibióticos, por ejemplo: penicilina, cefalosporina

Características: Requiere molienda fina para mejorar la solubilidad y la biodisponibilidad.

● Vitaminas, por ejemplo: vitamina C, vitaminas B

Características:Altamente sensible al calor, adecuado para molienda a baja temperatura.

● Extractos de hierbas chinas, ejemplos: ginseng, astrágalo

Características: Es necesario molerlo finamente para mejorar la eficacia.

● Agentes biológicos, ejemplos: enzimas, proteínas

Características: Sensible a la temperatura, adecuado para funcionamiento a baja temperatura.

● Medicamentos sintetizados químicamente, ejemplos: aspirina, ibuprofeno

Características: Es necesario controlar el tamaño de las partículas para garantizar la eficacia y la estabilidad.

● Medicamentos micronizados, ejemplo: drogas inhaladas

Características: Se requieren partículas extremadamente finas para mejorar la absorción pulmonar.

● Excipientes, ejemplos: lactosa, celulosa microcristalina

Características:Necesita una molienda fina para mejorar la fluidez.

En resumen, el molino clasificador de aire juega un papel importante en la industria farmacéutica.

Si tiene alguna necesidad de un molino clasificador de aire u otro equipo de procesamiento de polvo, o desea obtener más información relacionada, por favor Contacte con nuestro personalEstamos a su servicio en cualquier momento.