درباره آسیاب آسیاب

آسیاب آسیاب در صنایع مختلف برای کاهش اندازه ذرات و آماده سازی مواد برای کاربرد گسترده تر ضروری است. آسیاب طبقه بندی هوا یکی از انواع آسیاب آسیاب است. به دلیل منحصر به فرد بودن عملکرد بسیار خوبی دارد مکانیزم و مزایا این مقاله به تجزیه و تحلیل در مورد ویژگی ها آسیاب طبقه بندی کننده هوا در مقایسه با آسیاب های آسیاب دیگر و کاربردهای برجسته در صنایع مختلف.

طبقه بندی آسیاب های آسیاب

آسیاب های آسیاب را می توان با توجه به طراحی و مکانیسم های مختلف به چند نوع تقسیم کرد:

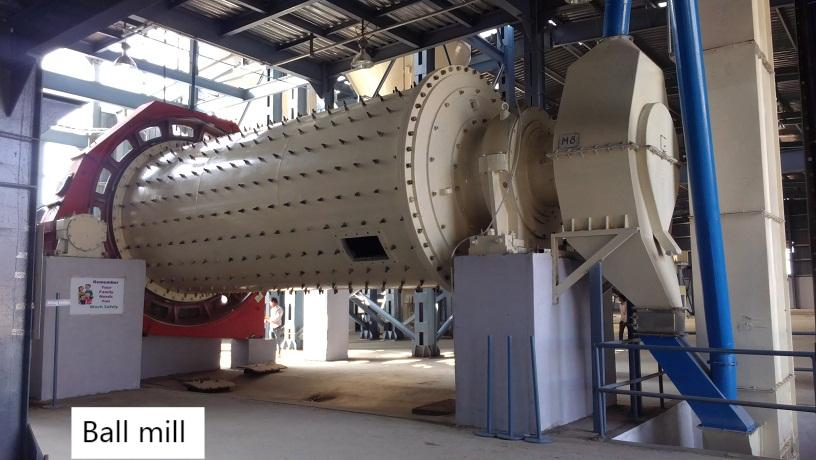

آسیاب گلوله ای: با استفاده از رسانه های آسیاب برای دستیابی به خرد شدن و ساییدن از طریق ضربه.

آسیاب چکشی: از چکش چرخان با سرعت بالا برای خرد کردن و آسیاب کردن مواد استفاده کنید.

آسیاب غلتکی: برای فشرده سازی و آسیاب کردن مواد از غلتک های استوانه ای استفاده کنید.

آسیاب طبقه بندی هوا: ترکیب آسیاب مکانیکی با طبقه بندی هوا برای طبقه بندی ذرات با ظرافت های مختلف.

مقایسه آسیاب طبقه بندی کننده هوا با آسیاب گلوله ای، آسیاب چکشی و آسیاب غلتکی زیر:

| ویژگی | آسیاب طبقه بندی هوا | آسیاب گلوله ای | آسیاب چکشی | آسیاب غلتکی |

| مکانیسم | طبقه بندی ضربه + هوا | ضربه + ساییدگی | تاثیر | فشرده سازی |

| کنترل اندازه ذرات | عالی (قابل تنظیم) | متوسط | محدود | متوسط |

| بهره وری انرژی | بالا | متوسط | کم | متوسط |

| تطبیق پذیری مواد | طیف گسترده ای از مواد | در درجه اول مواد فله | مواد کورس | مواد متوسط تا ریز |

| باقی مانده | متوسط | بالا | کم | متوسط |

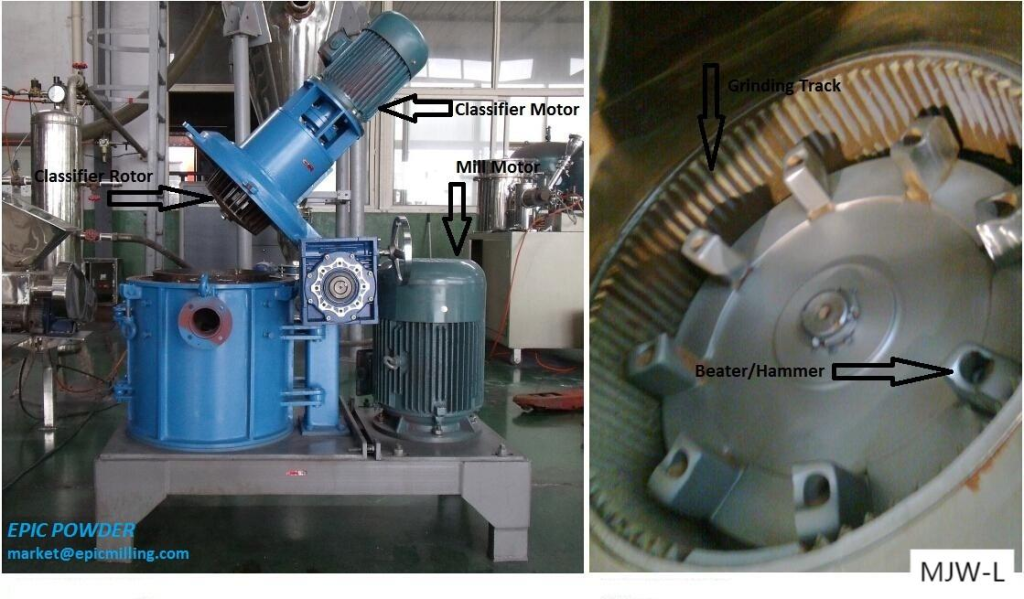

در زیر عکس هایی از آسیاب های مختلف از Qingdao Epic وجود دارد

ساختار آسیاب طبقه بندی هوا

محفظه سنگ زنی: قسمتی است که مواد در آن تغذیه و آسیاب می شود.

چرخ طبقه بندی: ذرات را با توجه به نیاز برای کاربردهای مختلف به ظرافت های مختلف جدا کنید.

سیستم جریان هوا: هوا را به محفظه سنگ زنی وارد می کند تا ذرات ریزتر را با ذرات واجد شرایط باقی بماند.

مزایای آسیاب طبقه بندی هوا

1. کنترل دقیق اندازه ذرات: طبقه بندی کننده هوا می تواند تنظیم دقیقی را در توزیع اندازه ذرات انجام دهد، این یک آسیاب ایده آل برای کاربردهایی است که به اندازه ذرات خاص نیاز دارند.

2. بهره وری انرژی: آسیاب طبقه بندی کننده هوا می تواند با به حداقل رساندن سنگ زنی بیش از حد به راندمان انرژی بالایی دست یابد، در حالی که این یک مشکل غیر قابل حل برای آسیاب های سنتی است.

3. کاربرد گسترده: آسیاب طبقه بندی کننده هوا می تواند طیف گسترده ای از مواد از جمله پلیمرها، سرامیک ها و مواد معدنی و غیره را مدیریت کند.

4. کاهش خطرات آلودگی: سیستم حلقه بسته قرار گرفتن در معرض آلاینده های خارجی را در طول پردازش به حداقل می رساند.

کاربرد آسیاب طبقه بندی هوا

1. صنایع غذایی: می توان از آن برای آسیاب ادویه جات ترشی جات، شکر و سایر مواد غذایی استفاده کرد، این محصولات به یکنواختی اندازه ذرات بالا نیاز دارند.

2. داروسازی: می توان از آن برای تولید پودرهای ریز برای فرمولاسیون دارویی با استانداردهای بهداشتی دقیق استفاده کرد.

3. مواد شیمیایی و پلاستیک: برای پردازش پلیمرها و سایر ترکیبات شیمیایی که به اندازه ذرات خاصی نیاز دارند استفاده می شود.

4. فرآوری مواد معدنی: همچنین می توان از آن در تولید پودرهای معدنی ریز برای ساخت و ساز استفاده کرد.

خلاصه

با توجه به مزایا و کاربرد گسترده، آسیاب طبقه بندی کننده هوا چشم انداز وسیع تری در آینده خواهد داشت. در پردازش عمیق پودرها ضروری است.

شرکت ماشین آلات پودر حماسی چینگدائو با مسئولیت محدود یک تولید کننده ماشین آلات پودر حرفه ای است. محصولات شامل: آسیاب: آسیاب طبقه بندی کننده هوا، آسیاب جت، آسیاب گلوله ای، آسیاب غلتکی و غیره. انواع مختلفی از طبقه بندی کننده های هوا. چندین نوع اصلاح کننده پوشش سطحی. تجهیزات کمکی، به عنوان مثال: کابینت کنترل، آسانسور سطل و گرد و غبار و غیره. محصولات را می توان با توجه به نیاز مشتری سفارشی کرد، "یک مشتری، یک طرح".

برای آسیاب طبقه بندی هوا، Qingdao Epic چهار نوع MJW-A، MJW-L، MJW-W، MJL-W را توسعه داده است.

اگر به محصولاتی از حماسه چینگدائولطفا تماس با کارکنان مستقیم، آنها همیشه در خدمت شما هستند.

در زیر عکس هایی از نوع آسیاب طبقه بندی کننده هوا از Qingdao Epic وجود دارد