Perkenalan

Bagaimana pengklasifikasi udara di ACM memisahkan partikel berdasarkan ukuran dan kepadatan partikel? Jawabannya adalah: melalui kombinasi gaya sentrifugal dan aliran udara, dan beberapa elemen lainnya.

Bagaimana unsur-unsur ini bekerja?

1. Pengenalan aliran udara:

Saat material dimasukkan ke dalam mesin pengklasifikasi udara (ACM), material memasuki ruang tempat aliran udara berputar berkecepatan tinggi dihasilkan. Aliran udara ini sangat penting untuk proses pengklasifikasian. Di bawah aksi aliran udara berkecepatan tinggi, material memasuki ruang pengklasifikasian melalui sistem pengumpanan. Aliran udara menahan material dalam gas yang mengalir berkecepatan tinggi, untuk membentuk aliran dua fase gas-padat. Hal ini dapat memastikan bahwa material terdistribusi dan diangkut secara merata.

2. Gaya sentrifugal:

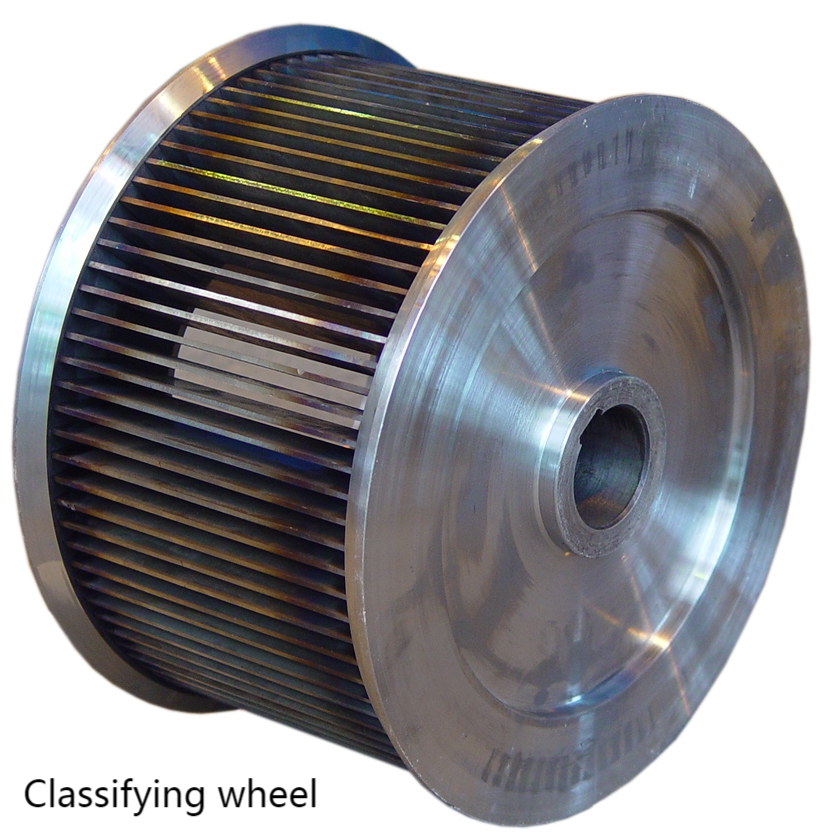

Pada pabrik pengklasifikasi udara, roda pengklasifikasi merupakan komponen utama. Saat roda pengklasifikasi berputar dengan kecepatan tinggi, ia akan menghasilkan gaya sentrifugal yang kuat. Gaya sentrifugal ini dapat memisahkan partikel kasar dan halus yang memasuki area klasifikasi dengan aliran udara yang meningkat. Partikel halus yang memenuhi persyaratan ukuran partikel melewati roda pengklasifikasi dan memasuki langkah berikutnya, sementara partikel kasar terlempar ke arah dinding ruang di bawah aksi gaya sentrifugal, lalu jatuh ke area penggilingan untuk penggilingan lebih lanjut.

3. Itu kelembaman dari partikel

Partikel halus: partikel yang lebih kecil memiliki inersia yang lebih rendah dan lebih mudah diserap oleh aliran udara. Partikel tersebut akhirnya dibuang melalui saluran keluar partikel halus yang telah ditentukan.

Partikel kasar: partikel yang lebih besar memiliki inersia yang lebih besar, sehingga aliran udara memiliki dampak yang lebih kecil pada partikel tersebut, dan partikel tersebut cenderung jatuh kembali ke ruang penggilingan untuk penggilingan lebih lanjut.

4. Mekanisme pemisahan

Dengan menyesuaikan parameter kecepatan aliran udara dan kecepatan rotor dapat meningkatkan efek pemisahan, dan mencapai distribusi ukuran partikel tertentu.

5. Sistem sirkulasi penggilingan ulang

Partikel berukuran besar yang tidak memenuhi persyaratan akan kembali ke ruang penggilingan untuk penggilingan lebih lanjut hingga mencapai kehalusan yang memenuhi syarat.

Ringkasan

Elemen-elemen di atas memungkinkan pengklasifikasi udara dalam ACM untuk memisahkan material dengan karakteristik fisik yang bervariasi secara efisien. Hal ini membuat ACM bekerja dengan baik dalam menggiling dan mengklasifikasi bubuk dalam industri farmasi, kimia, dan pengolahan makanan, dll.

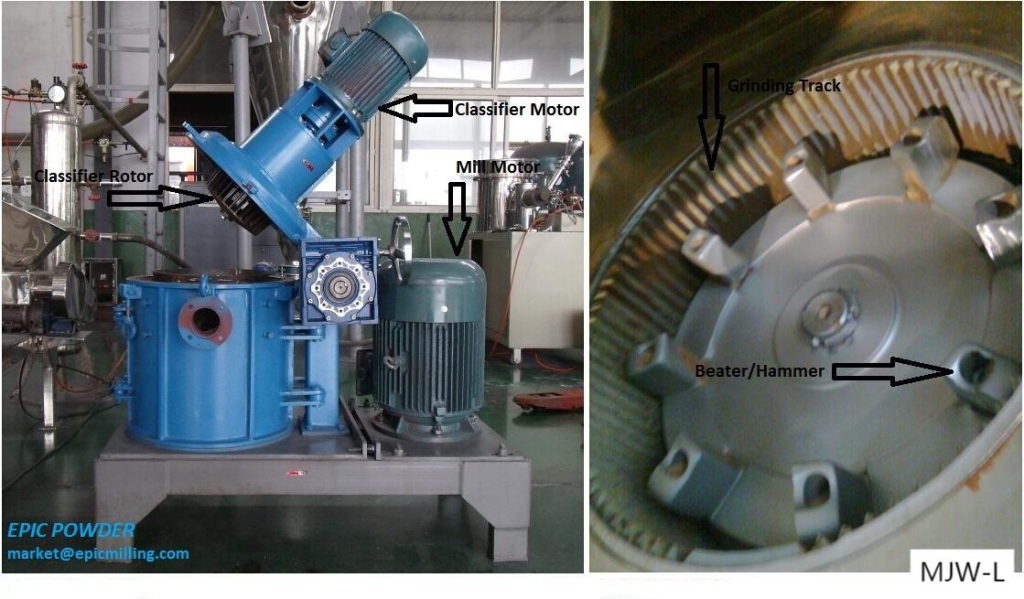

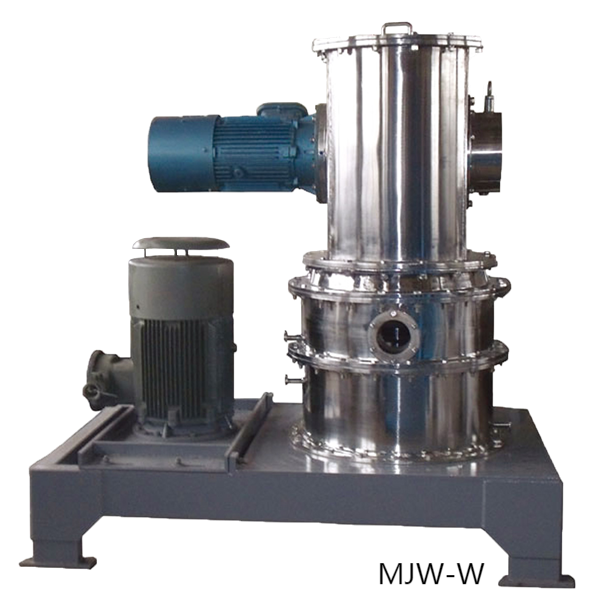

Qingdao Epic Powder Machinery Co., Ltd. adalah pabrikan mengkhususkan diri dalam produksi peralatan pengolahan bubuk. Air Classifier Mill adalah salah satu produknya, yang mencakup empat seri: MJW-A, MJW-L, MJW-W, MJL-W Dan Laboratorium ACM.

Produk dari Qingdao Epic meliputi:

– Pabrik: pabrik pengklasifikasi udara (ACM), pabrik bola, pabrik rol, pabrik jet, pabrik getaran, dan pabrik dampak, dll.

– Penggolong:empat seri pengklasifikasi udara: HTS, ITC, MBS dan CTC.

– Pengubah: pengubah pin-mill, pengubah turbo-mill, dan pengubah tiga-rol dsb.

– Peralatan bantu:kabinet kontrol, pengumpul debu Dan pengumpan sekrup dll.

– Pelanggan juga dapat menyesuaikan peralatan sesuai dengan kebutuhan mereka, satu pelanggan satu desain.

Jika Anda tertarik dengan pabrik pengklasifikasi udara atau produk lain dari Epik Qingdao, Tolong hubungi staf mereka secara langsung, mereka selalu siap melayani Anda.

Berikut adalah foto-foto dari Qingdao Epic dari referensi Anda.

Bahasa Indonesia: