Il mulino classificatore ad aria svolge un ruolo importante nella fase iniziale della produzione alimentare. Prendiamo come esempio la lavorazione dei cereali, come riso, grano o mais, tutto ciò di cui hanno bisogno è di essere finemente lavorati prima di essere ulteriormente trasformati in farina, amido o altre materie prime alimentari. Il mulino classificatore ad aria può classificare accuratamente i cereali e rimuovere impurità e particelle non qualificate. Questo processo può fornire materie prime di alta qualità per la successiva lavorazione alimentare. In questo articolo parleremo principalmente dei vantaggi del mulino classificatore ad aria nell'industria alimentare.

In quanto attrezzatura di macinazione avanzata, il mulino classificatore ad aria ha dimostrato numerosi vantaggi incomparabili nel campo della macinazione degli alimenti e sta gradualmente diventando la prima scelta di molte aziende alimentari.

Vantaggi del mulino classificatore ad aria nell'industria alimentare

— Igiene e sicurezza garantite

La produzione alimentare ha requisiti estremamente rigorosi in termini di condizioni igieniche. Il mulino classificatore ad aria adotta un design di struttura completamente chiuso, che può efficacemente evitare la miscelazione di impurità esterne ed eliminare l'inquinamento dall'ambiente circostante. Il materiale dell'interno del mulino ACM soddisfa gli standard di qualità alimentare e la camera è facile da pulire, riducendo il rischio di residui di cibo e crescita battericaDurante il funzionamento non vengono prodotte sostanze nocive per gli alimenti, il che può garantire l'igiene e la sicurezza degli alimenti fin dalla fonte.

— Dimensioni delle particelle controllate con precisione

Il mulino classificatore ad aria eccelle nel controllo delle dimensioni delle particelle, che risiede nella sua tecnologia di base e nelle caratteristiche di progettazione. Il mulino classificatore ad aria può controllare accuratamente le dimensioni delle particelle e la precisione della classificazione può raggiungere D97: 3 – 150μm, il che garantisce efficacemente il sapore, la consistenza e l'aspetto del cibo. Prendiamo come esempio la polvere di peperoncino. Per soddisfare le diverse esigenze di cottura, quando si prepara la polvere di peperoncino, diversi scopi di cottura richiedono diverse dimensioni delle particelle. Quando la polvere di peperoncino viene utilizzata in piatti freddi, il mulino ACM può classificare particelle più fini, che possono disperdersi meglio nella salsa fredda e migliorare il sapore; Quando la polvere di peperoncino viene utilizzata per preparare il condimento per barbecue, può classificare particelle più grossolane, che conferiscono una sensazione di masticazione unica e un rilascio di sapore durante il godimento delle persone barbecue.

— Elevata efficienza e risparmio energetico

La potente capacità di macinazione del mulino ACM può elaborare rapidamente grandi quantità di materie prime alimentari. Ciò riduce notevolmente il ciclo di produzione. Nel frattempo, è dotato di un sistema di circolazione dell'aria ottimizzato, riducendo significativamente il consumo di energia. Rispetto alle tradizionali apparecchiature di macinazione alimentare, il mulino ACM può risparmiare 30% - 50% di consumo di elettricità. Ciò consente di risparmiare molti costi di produzione per le aziende e migliora i vantaggi economici.

— Efficace ritenzione dei nutrienti

Come trattenere al massimo i nutrienti durante la macinazione è l'obiettivo delle aziende di produzione alimentare. Durante il funzionamento, il mulino classificatore ad aria adotta una macinazione delicata con flusso d'aria per evitare la perdita di nutrienti alimentari dovuta a attrito eccessivo e temperatura elevata. A differenza della macinazione a impatto, il mulino ACM funziona a temperature più basse. Ciò protegge efficacemente i nutrienti sensibili al calore, come vitamine, minerali, ecc. Ciò soddisfa la richiesta dei consumatori di cibo sano.

SCEGLI EPIC POWDER, SCEGLI PROFESSIONAL

Azienda: Qingdao Epic Powder Machinery Co., Ltd. è un produttore specializzata nella produzione di attrezzature per la lavorazione delle polveri. I nostri prodotti includono: mulino classificatore ad aria, mulino a sfere, mulino a cilindri, mulino a getto, mulino turbo, classificatori ad aria e modificatore a perni, modificatore a tre rotori, ecc.

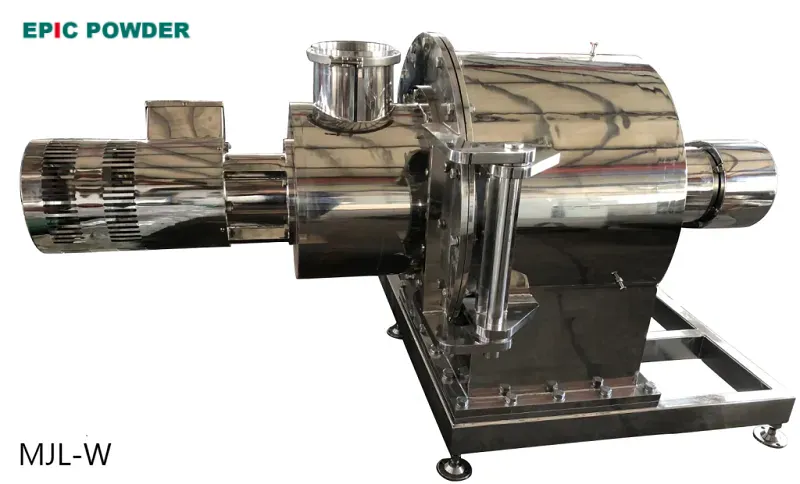

Il nostro mulino classificatore ad aria comprende quattro tipologie: MJW-W, MJW-L, MJW-A, MJL-W. Nell'industria di trasformazione alimentare, il nostro ACM è stato utilizzato per macinare riso, grano, mais, farina di manioca e peperoncino in polvere, con prestazioni eccellenti, qualità stabile e ottimi feedback da parte dei clienti.

Se hai esigenze o domande correlate sul mulino classificatore ad aria, o vuoi conoscere maggiori dettagli, non esitare a contattarci contatta il nostro staff, siamo sempre al vostro servizio.