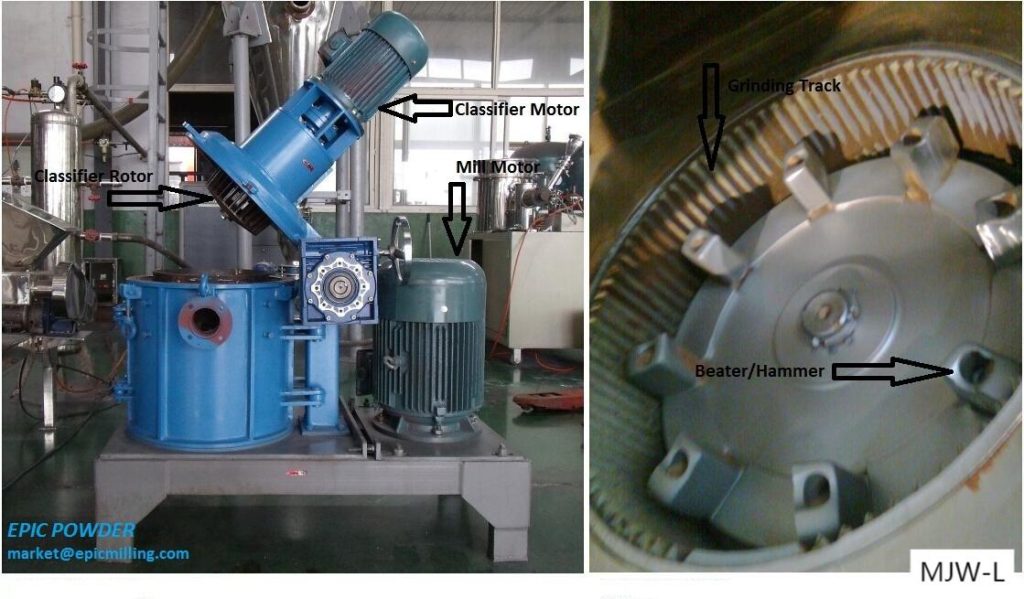

空気分級機(ACM)は、非常に効率的な粉砕装置であり、建材、 冶金 空気分級ミルは、主に供給ポート、粉砕室、分級ホイール、分級室、排出ポートなどで構成されています。空気分級ミル(ACM)の設計上の特徴により、清掃が容易になります。以下で詳細に分析してみましょう。

デザインの特徴

1. デュアルチャンバー設計

空気分級ミルは通常、粉砕室と分級室が別々になっている二重室設計を採用しています。この設計により、各コンポーネントの洗浄が容易になり、洗浄効率が向上します。

2. ヒンジ式ミルカバー

空気分級ミルにはヒンジ付きカバーが装備されており、作業員がミルの内部に触れて蓄積したほこりや汚れを取り除くのに役立ちます。ヒンジ付きカバーの設計は、ACM の清掃が容易なもう 1 つの理由です。

3. コンパクトなローターアセンブリ

空気分級ミルのローターは通常、簡単に洗浄できるようにコンパクトに設計されています。この設計により、ACM のメンテナンスと洗浄が容易になります。

上記の設計はすべて ACM のクリーニングに役立ちます。これらの設計は、クリーニング時間とメンテナンス コストを節約するだけでなく、運用効率も向上させます。

青島エピックパウダー機械株式会社 は メーカー 粉体機械の製造を専門としています。

の 主な製品は次のとおりです。

– ミルズ: ボールミル、空気分級機(ACM)、 ローラーミルジェットミル、ターボミル、インパクトミルなど。

— 空気分級ミルには 4 つのシリーズがあります。 MJW-W, MJW-L, MJW-A, MJL-W、 そして ラボACM.

– 分類子: 4つのシリーズの空気分級装置が含まれます。 HTS, 国際貿易委員会、MBS および CTC。

– 表面コーティングm香料: ピンミルモディファイア, ターボミルモディファイア 3本ロールミル改質器等

– 付帯機器: 制御盤, 集塵機 と スクリューフィーダーなど

– 顧客は実際のニーズに応じて製品をカスタマイズできます。 顧客 1 人につき 1 つのデザイン。

エアクラシファイアミル(ACM)に興味があるなら 青島エピック, スタッフにお問い合わせください 直接ご連絡いただければ、いつでも対応させていただきます。

以下は写真です 青島エピック ご参考までに。