空気分級ミルは、粉砕と分級の装置を組み合わせた高度な装置であり、さまざまな用途に合わせて特定の粒度分布を持つ微粉末を生成できます。

一般的に言えば、 空気分級機ミル 主に以下の要因によって影響を受けます。

1. 分類ホイールの速度

分級ホイールの回転速度は、粒度分布に直接影響を与える重要な要素です。速度が速いほど分離効率が上がり、粗い粒子をより多く再粉砕できます。これにより、より細かい粒子を確実に得ることができます。逆に、速度を遅くすると、粒子が粗い製品になります。

2. 空気の流れと速度

気流 材料をミルに輸送するためには、空気の流れが不可欠です。製品の最終的な細かさに重要な役割を果たします。空気の流れを増やすと、粒子が粉砕室を通過する速度が速くなり、粉砕時間が短縮され、粒子のサイズが粗くなります。逆に、空気の流れが少ないと粉砕時間が長くなり、粒子が細かくなります。したがって、一定の空気流量を維持しながら、空気の流れを調整します。 速度 分類ホイールにより分類性能が向上します。

3. 送り速度

材料がミルに供給される速度は、製品の細かさに大きく影響します。供給速度を上げると、粉砕時間が不十分になるため、通常は製品が粗くなりますが、供給速度を下げると、より細かい粒子が得られます。

4. ミル速度

ミル自体の速度もパフォーマンスに影響します。ミルの速度が速いほど、粒子への衝撃力が増し、より細かい粉砕効果が得られます。ただし、過度の摩耗や過熱を避けるために、この操作は他の操作パラメータとバランスをとる必要があります。

5. 飼料の粒度分布

供給原料の初期の粒度分布は、分類効率に大きく影響します。粗い供給原料 (40 ミクロン以上) は、一般に細かい供給原料よりも分類が容易です。粒度分布が明確な供給原料は、分離効率と全体的なパフォーマンスを向上させることができます。

6. 密度 粒子の形状

粒子の密度と形状は分級効率に影響します。密度の高い粒子は、密度の低い粒子とは異なる処理が必要になる場合があります。一方、不規則な形状は、ミル内の空気抵抗と流れのダイナミクスに影響を与える可能性があります。粒子の形状と空気の流れの相互作用は、分級効率に影響を与える可能性があります。

7. 飼料の水分含有量

原料の水分含有量が高いと凝集を引き起こし、効率が低下します。空気分級ミルの最適な性能を維持するには、水分含有量を制御することが不可欠です。

8. 温度制御

動作温度は、粉砕および分類中の材料特性に影響を与える可能性があります。たとえば、冷却空気は熱に敏感な材料の過熱を防ぎ、粉砕能力を高めることができます。

結論

要約すると、 空気分級機ミル 上記の要素のバランスが必要です。これらの要素がどのように相互作用するかを理解することで、オペレーターは必要な粉末を高効率かつ低エネルギー消費で実現できるようになります。

青島エピックパウダー機械株式会社は、粉体処理装置の製造を専門とするメーカーです。その製品には以下が含まれます。

– ミル: 空気分級機ミルボールミル、ローラーミル、ジェットミル、振動ミル、インパクトミルなど。

– 分類装置: 空気分類装置の 4 つのシリーズ: HTS、ITC、MBS、CTC。

– 改質装置:ピンミル改質装置、ターボミル改質装置、3ローラー改質装置など

– 付帯機器:制御盤、集塵機、吸引ファン等

– 顧客はニーズに合わせてカスタマイズすることもできます。「顧客1人につき1つのデザイン」。

空気分級機やその他の製品に関するご要望やご質問がございましたら、 スタッフに連絡 から 青島エピック 直接ご連絡いただければ、いつでも対応させていただきます。

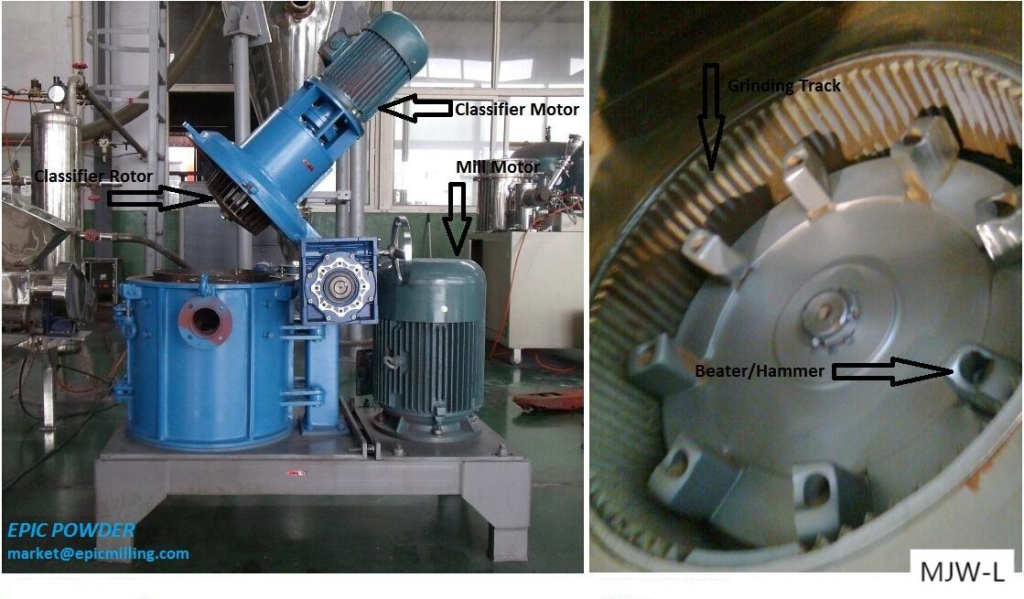

以下は、空気分級ミル用の Qingdao Epic の空気分級ミルの写真です。