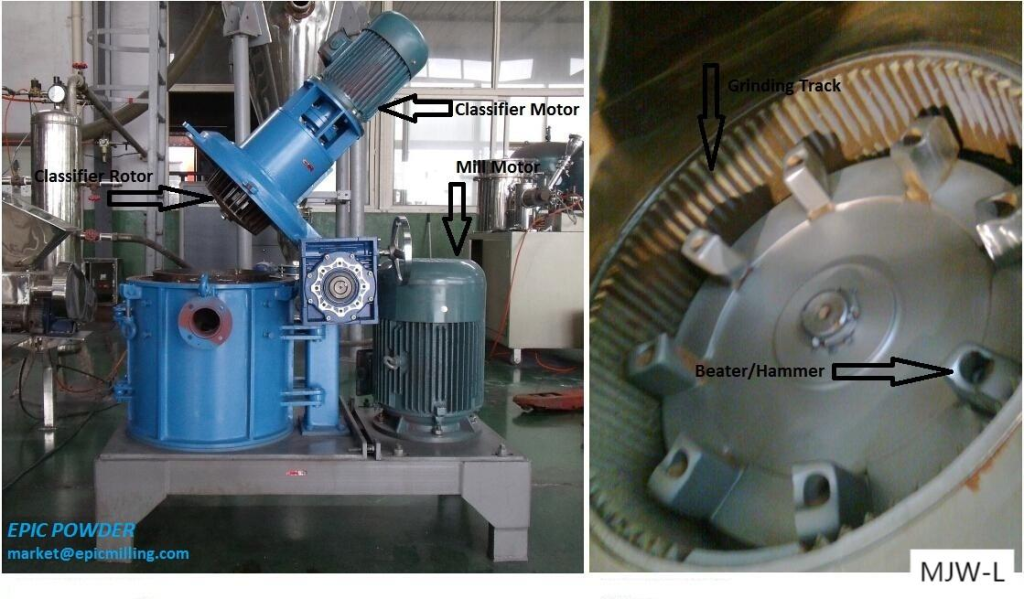

Het classificerende wiel in de luchtclassificatiemolen (ACM) speelt een cruciale rol in het maalproces. De hoofdfunctie van het classificerende wiel in de luchtclassificatiemolen is het classificeren van poederdeeltjes door fijnheid.

De rollen van het classificatiewiel in de luchtclassificatiemolen omvatten met name de volgende aspecten:

1. Voorslijpen van het materiaal

Wanneer het materiaal de maalkamer binnengaat, begint het classificatiewiel te werken. Door middel van hogesnelheidsrotatie kan het classificatiewiel een sterke centrifugale kracht genereren, zodat het materiaal classificatie met centrifugale kracht kan bereiken. Door de snelheid van het classificatiewiel en de grootte van de classificatieopening aan te passen, kan het materiaal in verschillende klassen worden geclassificeerd om aan verschillende behoeften in verschillende toepassingen te voldoen.

2. Luchtstroominductie

Classificerend wiel kan de snelheid en richting van de luchtstroom aanpassen. Op basis van de structuur en rotatie kan het classificerend wiel de snelheid en richting van de luchtstroom aanpassen. Wanneer materiaal door de waaier van de classificator gaat, zal de hogesnelheidsrotatie van de wielschijf het poeder scheiden en grove deeltjes op de wielschijf achterlaten voor hermaling.

3. Behandeling van deeltjes

Terwijl de deeltjes naar het classificerende wiel stijgen, komen ze twee tegengestelde krachten tegen: de centrifugale kracht van het classificerende wiel en de luchtweerstand van de luchtstroom. De fijnere deeltjes worden minder beïnvloed door de centrifugale kracht en verlaten de molen met de luchtstroom, terwijl de grovere deeltjes terug in de maalkamer worden gegooid voor verdere vermaling.

4. Parameters aanpassen

Door de snelheid van het classificatiewiel tijdens de werking aan te passen, kan de deeltjesgrootte worden gecontroleerd. Een hogere snelheid kan de deeltjesgrootte verhogen. middelpuntvliedende kracht en filteren grotere deeltjes effectiever, terwijl lagere snelheid meer fijne deeltjes doorlaat. De structuur van het wiel, inclusief de hoogte en het aantal waaiers, kan ook de luchtstroomsnelheid en classificatie-efficiëntie beïnvloeden.

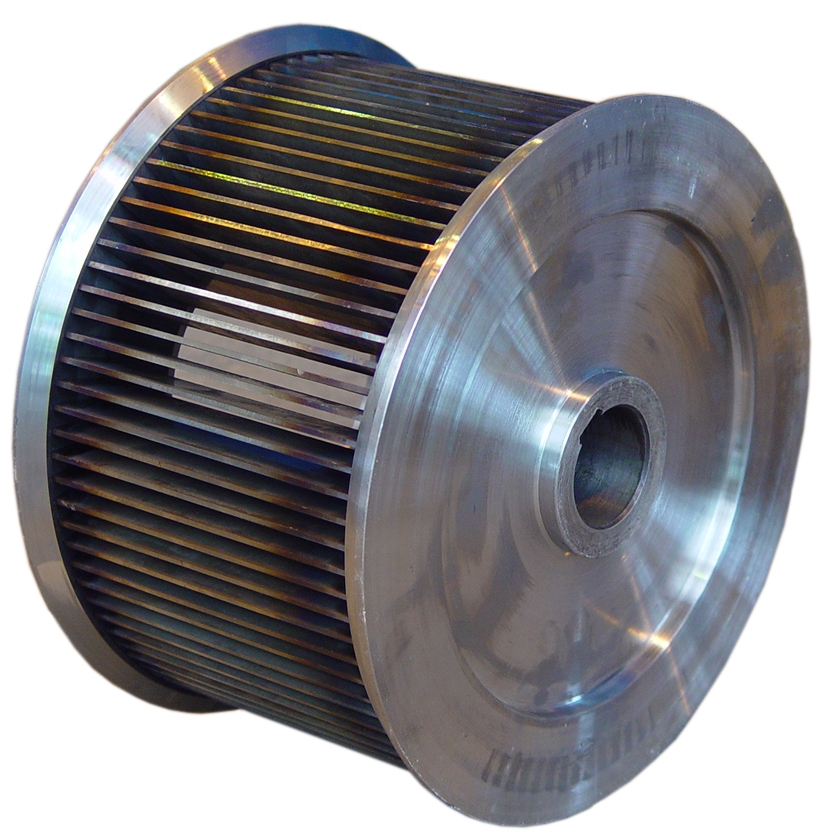

Classificatiewiel van Qingdao Epic hieronder

5. Continue werking

Het hele systeem werkt in een gesloten lus, waarbij grove deeltjes blijven recirculeren totdat ze de gewenste fijnheid bereiken. Vergeleken met een systeem dat een aparte classificatiestap vereist, kan de integratie van slijpen en classificatie binnen één enkele eenheid de werkefficiëntie verbeteren en de operationele kosten verlagen.

Samenvatting

Het classificerende wiel in de luchtclassificatiemolen is van vitaal belang om een nauwkeurige deeltjesgrootteverdeling te bereiken, omdat het de centrifugale kracht en luchtweerstand in een dynamische luchtstroomomgeving in evenwicht kan brengen. Dit ontwerp heeft als voordeel dat het materialen efficiënt kan verwerken en operationele flexibiliteit kan behouden.

Qingdao Epic Powder Machinery Co., Ltd. is een fabrikant gespecialiseerd in de productie van apparatuur voor poederverwerking.

Tot de producten behoren:

– Molen: luchtclassificatiemolen, kogelmolen, walsmolen, straalmolen, trilmolen en slagmolen etc.

– De luchtclassificatiemolen omvat: MJW-W, MJW-A, MJW-L, MJL-W En Luchtclassificatiemolen in laboratorium.

– Classifier: vier series luchtclassifiers: HTS, ITC, MBS en CTC.

– Modifier: pin-mill modifier, turbo-mill modifier en three-roller modifier etc.

– Hulpapparatuur: schakelkast, stofafzuiger en emmerlift etc.

– Klanten kunnen ook het ontwerp aanpassen aan hun eigen behoeften: één klant, één ontwerp.

Als u relevante behoeften of vragen heeft, neem dan contact met ons op. contact personeel van Qingdao-epos rechtstreeks, ze staan altijd voor u klaar.

Hieronder vindt u vier series luchtclassificatiemolens van Qingdao Epic ter referentie.