Air classifier mill is a high-efficienct powder grinding equipment that integrates grinding and classifying. Its core working principle is to grind and classify material through high-speed rotating grinding rotor and classifying wheel.

Although air classifier mill is easy to operate, we still need to pay attention to the following precautions to ensure efficient operation of the equipment and extend its service life.

Precautions for using air classifier mill

1. Equipment installation

Solid foundation: we should install air classifier mill on a solid foundation to avoid damage to the equipment or impact on grinding due to vibration.

Good ventilation environment: Good ventilation is necessary, ’cause it can avoid dust accumulation and ensure a safe operating environment.

2. Material selection

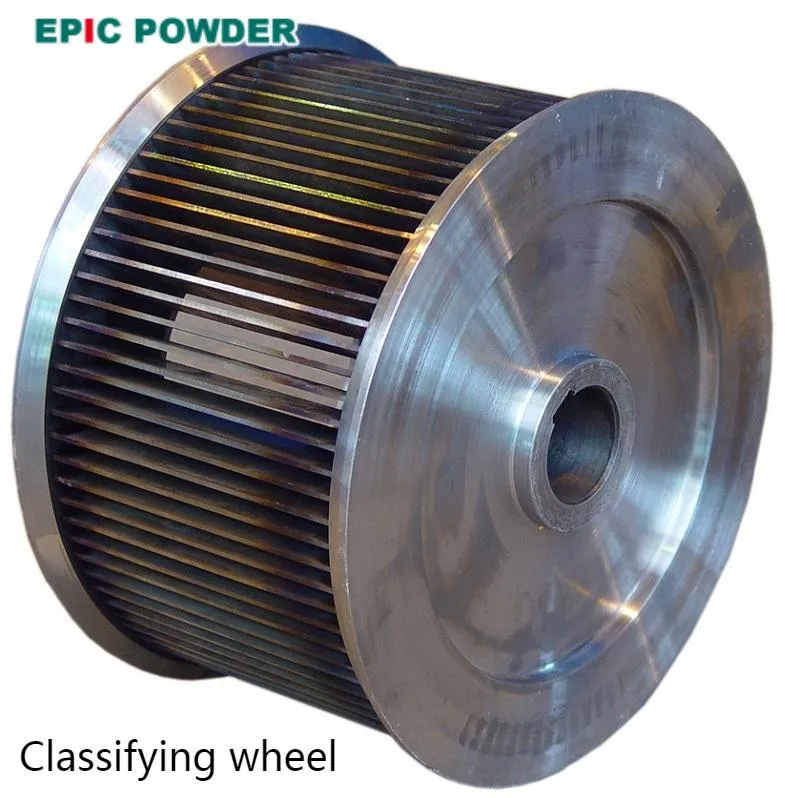

Material hardness: Air classifier mill is suitable for materials with medium hardness or below. Materials that are too hard may cause accelerate equipment wear and even damage the rotor or classifying wheel.

Material humidity: Excessive material humidity may cause blockage or adhesion in grinding chamber, affecting the grinding effect. For material with high humidity (usually the humidity should be within 2%), it is better to dry it first.

3. Operation parameters

Feeding speed: The feeding speed should be uniform. Too fast may cause equipment overload, while too slow may affect production efficiency. The feeding speed should be reasonably adjusted according to the properties of the material and the processing capacity of the equipment.

Classifying wheel speed: The speed of classifying wheel directly affects the particle size distribution of the material. The higher the speed, the finer the classification fineness, and the lower the speed, the coarser the classification fineness. The speed of classifying wheel should be reasonably adjusted according to product requirements.

Air volume and air pressure: The adjustment of air volume and air pressure has an important influence on grinding efficiency and classification accuracy. Excessive air volume may result in the inability to effectively collect fine particles, while insufficient air volume may cause accumulation of the material in grinding chamber.

4. Equipment maintenance

Regular inspection: Regularly check the wear of key components, such as: the rotor, classifying wheel, and the fan, and replace severely worn components in time to ensure the normal operation of air classifier mill.

Lubrication and maintenance: Regularly lubricate bearings, gears and other moving parts to reduce friction loss and extend the service life of the equipment.

Clean up accumulated materials: Regularly clean up accumulated materials in grinding chamber and grading area to prevent materials from clogging or sticking and affecting the grinding effect.

5. Safe Operation

Protective equipment: Operators should wear protective glasses, masks,etc. to avoid dust inhalation or injury from splashes.

Emergency shutdown: If abnormal noise, vibration or overheating occur during the operation, stop the equipment immediately for inspection.

6. Environmental requirements

Dust control: Air classifier mill will generate a lot of dust during operation, so it should equip with effective dust removal equipment, such as bag filter, to ensure that dust emissions meet environmental protection requirements.

Noise control: In order to prevent the noise generated during equipment operation from harming the operators, sound insulation measures should be taken, or the operators should equip with protective equipment, such as earplugs.

Conclusion

Through reasonable operation and maintenance, air classifier mill can provide enterprises with efficient and stable powder processing solutions, extend the service life of the equipment, and ensure production safety and environmental compliance.

Choose professional, choose Epic Powder

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Our products include: air classifier mill, ball mill, jet mill, roller mill, various air classifiers, powder coating and modification equipment and related auxiliary equipment. Among them, air classifier mill includes four types: MJW-L, MJW-W, MJW-A, MJL-W. They are optimized based on traditional air classifier mill, with stable quality, excellent performance, and high reputation among customers.

Based on many years production, we have accumulated rich experience and technology, and we can provide you with one-stop solutions from equipment selection, scheme design to installation and commissioning, and after-sales service.

If you have related needs for air classifier mill, or want to know more detailed information about our products, please feel free to contact our staff directly, we are always ready to serve you.