หน้าที่หลักของเครื่องบดคือการแปรรูปวัสดุแข็งให้เป็นผง ซึ่งช่วยให้ผสมได้สม่ำเสมอ ความคล่องตัว ของวัสดุและปรับปรุงคุณภาพผลิตภัณฑ์ในที่สุด มีเครื่องบดหลายประเภท บทความนี้จะวิเคราะห์การเปรียบเทียบระหว่างเครื่องบดแยกประเภทด้วยอากาศกับเครื่องบดแบบกระแทก เครื่องบดแบบลูกบอล และเครื่องบดแบบเจ็ท เพื่อสำรวจความแตกต่างในแง่ของขนาดอนุภาคที่สามารถรับได้

1. ข้อได้เปรียบด้านขนาดอนุภาคของเครื่องแยกอากาศ

เครื่องแยกอากาศเหมาะสำหรับขนาดอนุภาคที่หลากหลายตั้งแต่ไมครอนไปจนถึง มิลลิเมตรขนาดอนุภาคที่กว้างนี้ทำให้มีความยืดหยุ่นสูงในการใช้งานที่หลากหลาย เครื่องบดแยกอนุภาคด้วยอากาศสามารถกระจายขนาดอนุภาคได้แคบ โดยมีขนาดอนุภาคอยู่ระหว่าง 5 ถึง 10 ไมครอน ความละเอียดนี้มีความสำคัญในบางอุตสาหกรรม เช่น อุตสาหกรรมยา ซึ่งความสม่ำเสมอส่งผลโดยตรงต่อประสิทธิภาพและคุณภาพของยา

2. การเปรียบเทียบกับโรงสีอื่น ๆ

❊ เมื่อเทียบกับเครื่องโม่แบบกระแทก

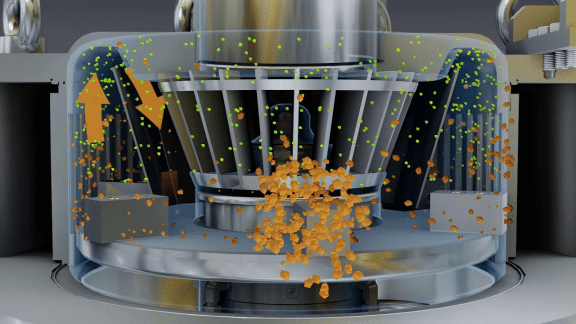

เครื่องบดแบบกระแทกแบบดั้งเดิมสามารถผลิตอนุภาคที่มีขนาดใหญ่กว่าได้เท่านั้น ซึ่งทำให้ความละเอียดที่ได้มีจำกัด ในขณะที่เครื่องบดแบบแยกประเภทด้วยลมสามารถจำแนกขนาดเม็ดได้ระหว่างขั้นตอนการบด ทำให้ควบคุมผลิตภัณฑ์ขั้นสุดท้ายได้แม่นยำยิ่งขึ้น

❊ เมื่อเทียบกับเครื่องบดลูกบอล

แม้ว่าเครื่องบดแบบลูกบอลจะสามารถบดอนุภาคละเอียดได้ แต่โดยปกติแล้วจะต้องใช้เวลาในการประมวลผลนานกว่า และอาจก่อให้เกิดความร้อนมากเกินไป ในขณะที่ความร้อนมากเกินไปอาจส่งผลต่อผลการบดของวัสดุที่ไวต่อความร้อน ในทางกลับกัน เครื่องบดแบบแยกอากาศจะทำให้เกิดความร้อนน้อยลงเนื่องจากการควบคุมการไหลของอากาศที่มีประสิทธิภาพ ซึ่งทำให้เครื่องบดแบบแยกอากาศเหมาะสำหรับการบดวัสดุที่ไวต่อความร้อน

❊ เมื่อเทียบกับเครื่องเจ็ทมิลล์

เครื่องโม่แบบเจ็ทสามารถผลิตอนุภาคละเอียดและกระจายตัวได้แคบ แต่บ่อยครั้งต้องใช้พลังงานป้อนเข้าที่สูงกว่า และอาจมีข้อจำกัดเกี่ยวกับประเภทของวัสดุ เช่น วัสดุที่แข็งกว่าจะจัดการได้ยาก ในขณะที่เครื่องโม่แบบแยกอากาศสามารถนำเสนอโซลูชันที่ประหยัดพลังงานมากกว่า แต่ในขณะเดียวกันก็รักษาความสามารถในการบดวัสดุต่างๆ ไว้ได้

บทสรุป

จากที่กล่าวมาทั้งหมด เราสามารถสรุปได้ว่าเครื่องบดแยกอากาศมีข้อได้เปรียบที่สำคัญเหนือเครื่องบดอื่นๆ ในการควบคุมขนาดอนุภาค ข้อได้เปรียบเหล่านี้ทำให้เครื่องบดแยกอากาศมีประสิทธิภาพที่ยอดเยี่ยมในการจัดการกับความละเอียดของอนุภาค โดยเฉพาะอย่างยิ่งในอุตสาหกรรมที่ต้องการการกระจายอนุภาคที่แม่นยำ เช่น อุตสาหกรรมยาและเคมี เครื่องบดแยกอากาศแสดงให้เห็นถึงคุณค่าการใช้งานที่ไม่เหมือนใคร

บริษัท ชิงเต่าอีพิคผงแมชชีนเนอรี่ จำกัด. เป็น ผู้ผลิต มีความเชี่ยวชาญด้านการผลิตอุปกรณ์แปรรูปผง

ผลิตภัณฑ์ของเราประกอบด้วย:

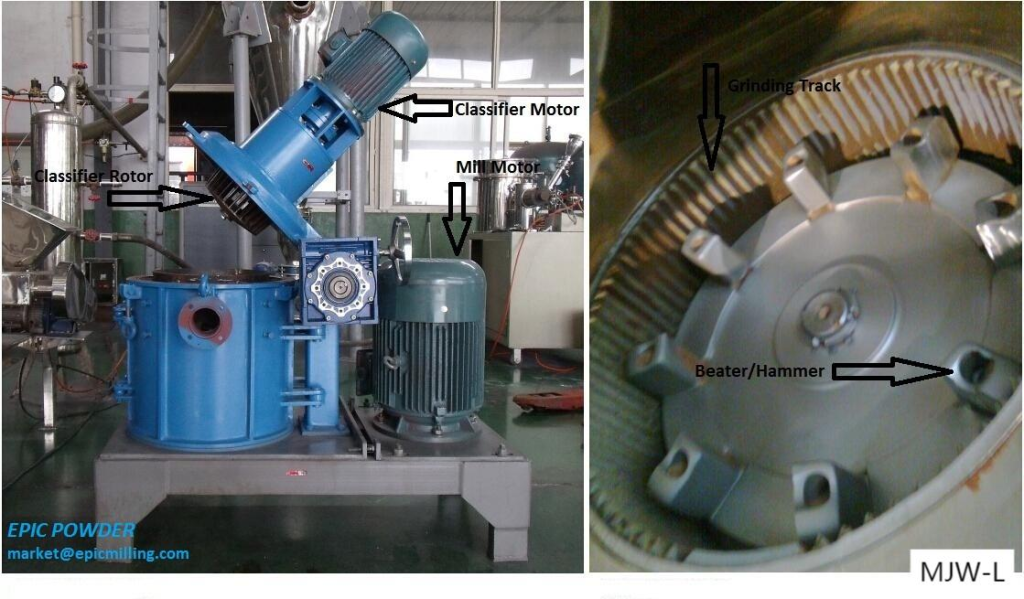

– โรงสี:เครื่องบดแยกอากาศ เครื่องบดลูกบอล เครื่องบดลูกกลิ้ง เครื่องบดเจ็ท เครื่องบดแบบสั่นสะเทือน และเครื่องบดแบบกระทบ ฯลฯ เครื่องแยกอากาศประกอบด้วย: เอ็มเจดับบลิว-ดับบลิว, เอ็มเจดับบลิว-แอล, เอ็มเจดับบลิว-เอ, เอ็มเจแอล-ดับบลิว, และ เครื่องบดแยกอากาศในห้องปฏิบัติการ

– ตัวจำแนกประเภท:เครื่องจำแนกอากาศ 4 รุ่น คือ HTS, ITC, MBS และ CTC

– ตัวปรับเปลี่ยน: ตัวปรับเปลี่ยนพินมิลล์ ตัวปรับเปลี่ยนเทอร์โบมิลล์ และตัวปรับเปลี่ยนมิลล์สามลูกกลิ้ง ฯลฯ

– อุปกรณ์ช่วย: ตู้ควบคุม, เครื่องดูดฝุ่นและ พัดลมดูด ฯลฯ

– ลูกค้ายังสามารถปรับแต่งตามความต้องการของตนเองได้อีกด้วย ลูกค้าหนึ่งรายหนึ่งการออกแบบ.

หากท่านสนใจเครื่องแยกอากาศหรือสินค้าอื่นๆจาก ชิงเต่าเอปิค, โปรด ติดต่อเจ้าหน้าที่ จาก Qingdao Epic โดยตรง พวกเขาพร้อมให้บริการคุณเสมอ

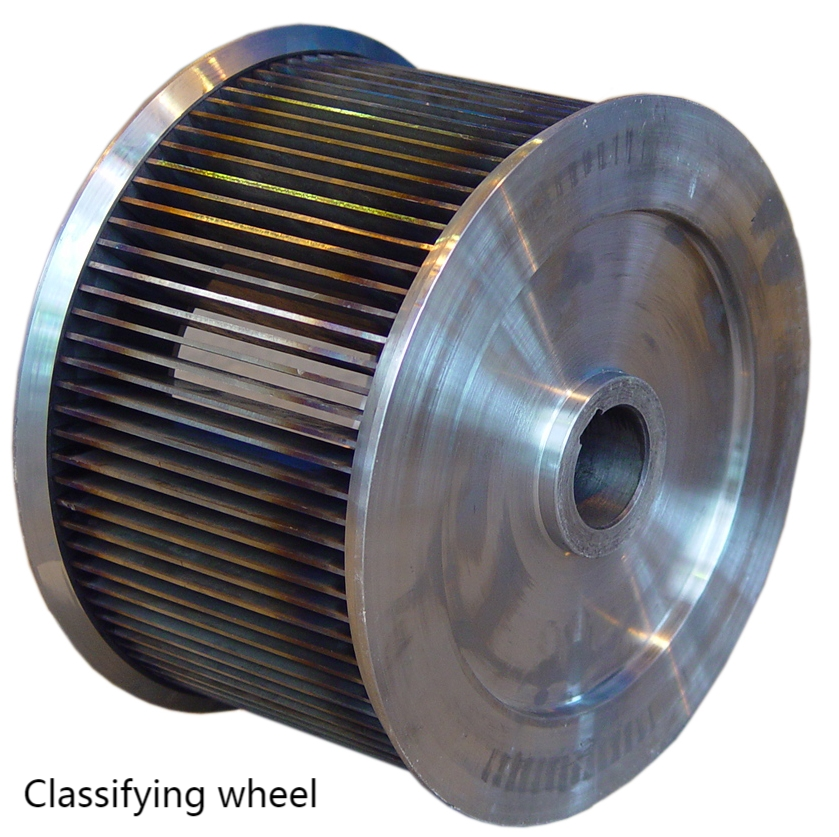

ด้านล่างนี้เป็นภาพถ่ายจาก Qingdao Epic เพื่อใช้อ้างอิงของคุณ